Extrication Tips: October 2009

Randy Schmitz

Features Extrication TrainingIn June I had an opportunity to work on concrete truck rollover accident simulations. The idea came to me after my department responded to a concrete-truck-versus-car accident that resulted in five fatalities – an entire family taken in the blink of an eye.

In June I had an opportunity to work on concrete truck rollover accident simulations. The idea came to me after my department responded to a concrete-truck-versus-car accident that resulted in five fatalities – an entire family taken in the blink of an eye. The truck hit the car at a high rate of speed, pushing it several meters and turning it into a crumpled mass of twisted steel, plastic, tires and bodies. The extrication was no picnic, even for the most seasoned rescuer, particularly when young children were involved. These are the types of calls that we all dread and usually stick in our minds for quite some time. But we need to focus on the task at hand to do our best in the face of an extremely bad situation.

|

|

| Photos by Randy Schmitz Photo 1: Determine stability of drum. |

|

|

|

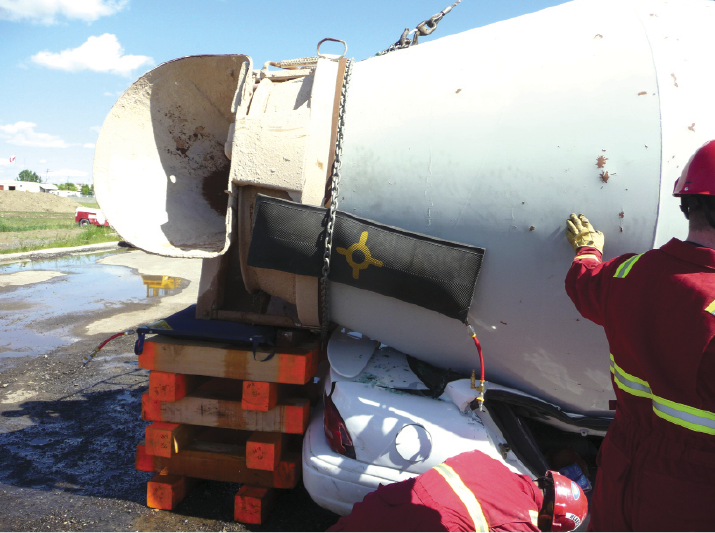

| Photo 2: Secure the drum. |

|

|

|

| Photo 3: Work from most stable side. |

|

|

|

| Photo 4: Secure strut base plates. |

|

|

|

| Photo 5: Use minimum of two step ladders. | |

|

|

| Photo 6: Heavy wrecker should lift truck. |

|

|

|

| Photo 7: Locate solid lift surface. | |

|

|

| Photo 8: Pre-plan the lift. |

|

|

|

| Photos 9: Use cable pullers or turfers. |

|

|

|

| Photos 10: Pull vehicle in controlled manner. |

Application

When managing incidents with large vehicles, keep in mind they are different than standard automobile entrapment situations. The scene can be complicated by the size and weight of the vehicle and its cargo. However, by following basic information about large vehicles, understanding the problems and applying extrication solutions, you can become proficient in handling accidents with large trucks.

The following deals with stabilization and lifting practices relating to a concrete truck that has rolled over on to a typical four-door sedan. We will follow a format called the Five-step discipline for an over-turn or under-ride:

- Identify the cargo;

- Stabilize the large vehicle;

- Lower the smaller vehicle;

- Lift the larger vehicle;

- Separate the vehicles if warranted and perform extrication.

First let’s talk about a few characteristics that pertain to concrete trucks. Concrete trucks or haulers can come in a variety of shapes, sizes and designs. The type and size depicted here is a common size you will encounter, known as rear-discharge mixers. These trucks can weigh anywhere from 20,000 pounds (9,100 kilograms) to 30,000 pounds (14,000 kilograms), and can carry roughly 40,000 pounds (18,000 kilograms) of concrete although many varying sizes of mixer truck are used. The most common truck capacity is about eight cubic yards or (6 m3). A cubic yard of concrete weighs about 4,000 pounds (1,800 kilograms). One cubic foot of concrete weighs roughly 150 pounds (70 kilograms). Spiral blades inside the drum keep the concrete fluid and towards the front of the drum as it rotates counter clockwise while in transit; once at the job site the drum-turning direction is reversed and the concrete is pushed out the back. In highly populated areas there could be 150 or more concrete trucks in operation. Concrete trucks are dangerous vehicles on the road if not driven under strict parameters. The high centre of gravity, excessive speed and taking corners too sharply are all factors in rollovers. In discussions with the larger concrete companies, some state they have as many as one or two rollover incidents a year. Aside from construction sites, which are common locations for rollovers, accidents involving concrete trucks can happen on ramps for highway exits and entrances; sometimes smaller vehicles driving next to cement trucks become trapped in a rollover.

Tactical strategies include the following:

- Size-up;

- Stabilization;

- Shutting down the engine;

- Disconnecting the batteries;

- Disentanglement and extrication;

- Scene termination.

Size-up

While size-up can be intimidating, a thorough size-up will bring even a complex truck incident to a successful conclusion. Standard motor vehicle accident size-up priorities still apply – including initial dispatch report, cargo identification, inner and outer circle surveys, hazard assessment, causality report, suppression management and additional resources called early. Get a heavy wrecker on its way. It is important to let dispatch know what size and type of large truck is involved so the proper capacity tow-truck/heavy wrecker can be dispatched; you don’t want one to arrive that won’t be able to perform a heavy lift.

Potential problems include:

- Severe crush factor and heavy entrapment of the causalities underneath the drum of the truck;

- A fully loaded rotating drum may become dislodged or even be torn off from the crash or overturn;

- Concrete product that has spilled out or on to other vehicles involved ( appropriate resources will need to be called to clean up this type of material; allow enough time for arrival as concrete generally has a set up time of 90 minutes or less);

- Diesel fuel tanks or “saddle tanks” may be leaking or ruptured. These are usually made of aluminium and can carry 190 to 250 litres of fuel. There will normally only be one fuel tank. Although diesel fuel is not a volatile as gasoline it can still be dangerous and ignite if splashed on engine components or hot pavement. Suppression foam should be applied to prevent the release of flammable vapours. A leak /spill containment kit may be on board and should be used.

Once these issues have been identified and addressed, the next priority is to make the truck safe to work around.

Stabilization of the larger vehicle (initial stabilization)

If contact with the driver is possible, ask to have the ignition turned off; if not, stabilization prior to rescuer entry into the cab is required. Block the tires with wheel chocks or lumber.

Depending on the truck’s resting position on its side, rescuers must determine if the rotating drum has been dislodged or has otherwise become unstable. There is not a lot holding the drum in place aside from the one to two-inch (25 to 50 millimetres) power take-off shaft that assists the rotation and the thin metal shroud at the rear of the drum that holds the roller guide wheels in place. (See photo 1.) If this needs to be addressed a grade-80 rescue chain should be used to secure the drum to the frame and make the truck safe to work around for rescuers and patients. (See photo 2.) In this case we used an inflated lift bag to take slack out of the chain; however, a chain boomer can also be used if one is available. The goal at this stage is to stop larger vehicles from any movement and possibly crushing down on the smaller vehicle, making things worse.

Stabilization can be done in a variety of ways; If a heavy wrecker becomes available cables, chains or slings can support the large vehicle in a matter of minutes. Other options are heavy-duty strut systems that can be used to secure the truck, or stacks of box cribbing. Choose the side of the truck that is most unstable and work from there. Try to locate the struts/box cribbing on strong areas such as frame rails. (See photo 3.) It is a good idea to secure the strut base plates to the ground with stakes for added stability. (See photo 4.) If timbers are available they may be used in conjunction with crib stacks.

Remember if your going to be lifting this truck using your own mechanical means, you may want to insert lifting bags in between the crib stack and the timber at this time. Opening the hood shroud will provide more options near the front end of the truck to find a good solid crib or strut placement point on the frame rails. Also, a minimum of two step-type ladders will be needed; you will be working at heights of more than 10 feet (3.5 meters) when dealing with trucks of this size. (See photo 5.) When the vehicle is considered stable, ensure ignition shut down if the driver could not do this initially. Entry into the cab may be done through a window or if access is limited, removal of the front windshield can usually be done effectively. Outer rubber gaskets that hold the windshield in place may be cut out with a sharp knife and can the windshield can often be removed in one piece.

Once inside look for any switches or buttons that indicate a power-take-off unit that rotates the drum and turn it off. Engage the braking system by pulling the bright yellow airbrake button on the dash.

Battery disconnection

Locate battery box, which could be under driver’s side step to the cab; if there is more than one bank of batteries, attempt to disconnect them all as they may be wired in series.

Disconnect/cut the positive terminal first, then negative and wrap with latex medical glove or tape.

Although some large vehicle manufacturers that are starting to install supplemental restraint systems such as airbags to protect the occupants, the main reason to disconnect the batteries is that they are a possible ignition source for fire.

Motor vehicle accidents, whether involving an impact to the front, rear or side of the vehicle, frequently result in the release of flammable fuel. Ignition of the fuel may be the result of a number of causes, however one common cause is the sparking of live wiring. Such sparking can take place not only in high voltage ignition systems but elsewhere in the vehicle’s wiring harness, which typically extends throughout the vehicle’s body. Even if the engine and alternator, have ceased to operate, the vehicle’s battery may continue to supply current to such circuits. The battery itself may also be crushed as a result of the accident, and its live terminal (typically the positive terminal) may come into contact with the metal frame or bodywork creating severe sparking.

Lower the smaller vehicle

Often there will be some survival space within the passenger compartment; if tunnelling into the vehicle through the trunk or side is the most efficient and safe for rescuers/ patients, then obviously every attempt should be made to do so. If after careful consideration this is not feasible, then an effort to create space between the truck and the car has to be analyzed. Try to think creatively; first look at the ground conditions. If the ground is soil, can you dig down under the tires to create space? Although unlikely, the tires may still have air in them. Could they be deflated, even a little to gain precious room? If the surface conditions allow, is removing the accessible tires altogether be an option?

Don’t forget about the suspension. It may be compressed from the weight of the truck, but adding a ratchet strap or come-along and compressing it even further could create extra space.

It will be beneficial to explore these options before attempting to lift or move the truck.

Lift the larger vehicle

Once all the possible options for lowering the smaller vehicle have been exhausted, lifting the truck is the only option left.

Again, this should be the job of a heavy wrecker, (See photo 6.) The alternative is to perform the evolution with high-pressure lift bags. This will take more time but can still be done effectively. Locating solid lift surfaces could be challenging but they can usually be found near the rear of the truck. We chose the hopper frame of the drum, which proved to be strong enough and had a sufficient amount of surface area to support our lift point. (See photo 7.)

The lift platform was built large enough to add additional cribbing to support our load as we lifted the truck. Always remember, if you lift an inch you must crib an inch. Pre-plan the lift, decide if the lifting height that is required for clearance can be done with one lift bag or two stacked on top of each other to gain sufficient height. (See photo 8.)

(For more info on lift bag procedures refer to the July 2007 edition)

Have crews monitor the lift from all four sides throughout the lifting evolution to be aware of any unwanted movement, potential load shift or unsafe conditions. If struts are used they too must be adjusted to follow the load as it is lifted. Once a suitable amount of clearance has been obtained between the bottom of the drum and top of the smaller vehicle’s roof, it is time to move onto the next step.

Separate the vehicles and perform extrication

Some rescuers may feel that moving a vehicle to perform extrication is controversial, however, an exception in this case is warranted due to rescuer safety and patient egress.

A controlled method is to carefully pull the vehicle out from underneath the stabilized concrete truck.

Equipment such as cable pullers or turfers, which can be used to lift or pull, are excellent tools for control and ease of use. (See photo 9.) Two 2,000-pound come-alongs will also work well. Find a couple of strong anchor points to secure the hooks. Removing the rims and hooking onto the lower control arms are options; just make sure they are intact and safe to support tension. Bumpers could be used to hook onto but a lower connection point seems to works best while moving the vehicle.

Carefully pull the vehicle out in a controlled manner; in our case pulling the rear end of the vehicle out first at an angle proved to be a very smooth process. (See photo 10.) With the vehicle free it is now in a position for good access to patients.

(Note: If concrete has spilled into the passenger compartment, this could have dire consequences for the patients that are trapped, as the concrete can start to solidify during the extrication. To buy precious time and stop the set of concrete you can add bags of pure sugar (white or brown) and a small amount of water to stop the chemical process of solidification, The sugar will react with the chemicals in the concrete and stop it from hardening. Soda pop such cola will also help but will not be as effective. Having a convenience store nearby would certainly benefit in a situation like this.)

Apply standard extrication techniques to complete patient removal. Although with a severely crushed roof the situation may look grim, you will be surprised of how much survival space there actually is.

The physical size, weight and structural strength of these trucks may be challenging. Working on heavy trucks requires a little extra knowledge and specialized tools. The incident commander must realize the limits of the department and use other resources and agencies such as commercial tow truck companies to assist in the rescue plan. To be comfortable with heavy vehicle extrication incidents you must train on these types of vehicles.

Local concrete plants, and large truck-wrecking yards usually have old concrete or cement trucks that have seen better days sitting around gathering rust. Why not ask for the truck to be donated to the fire department for training? A lot of times these companies will be more than happy to help ,if they know the truck will be put to good use.

In my case, Lafarge Canada donated five large concrete trucks.

All I did was ask and explain that they would provide an excellent training opportunity to hone our skills. This is also a great opportunity to foster a well-rounded working relationship with your local towing company. Invite them along to participate in the training (maybe you can get the truck towed to your training facility for free in the meantime). This will also allow you to discover each other’s capacities and limits – excellent knowledge to have the next time you respond to this kind of incidents.

Summary

You cannot fully appreciate the strength and magnitude of these vehicles until you work on them. Now is the time to see if your department has the required tools to do the job efficiently and safely. This may cause your department to revaluate its response protocols, dispatch questions, resource allocations and mutual-aid agreements Keep safe!

Calgary firefighter and extrication instructor Randy Schmitz has been involved in the extrication field for 16 years and has competed in all levels of extrication competition including world challenges. He is the Alberta chairman for Transport Emergency Rescue Committee in Canada, chairman of the T.E.R.C. Canada educational committee and a judge for T.E.R.C. Canada and U.S. He can be reached at rwschmitz@shaw.ca

Print this page