Extrication explanation

Randy Schmitz

Features Extrication TrainingA year ago, in the August 2009 edition of Fire Fighting in Canada, we talked about new vehicle technology and the challenges it presents for rescuers.

A year ago, in the August 2009 edition of Fire Fighting in Canada, we talked about new vehicle technology and the challenges it presents for rescuers. Innovations such as roof curtain airbags, seatbelt pre-tensioners and knee bolsters all protect vehicle occupants but pose challenges for rescuers attempting extrication. With myriad vehicle makes and models, it’s impossible for rescuers to remember the locations of all these new protection systems.

The Calgary Fire Department is running a pilot project with the Crash Recovery System software on three of its rescue trucks. CRS was developed by Netherlands-based Moditech Rescue Solutions www.moditech.com. It is a cost-effective solution that gives rescuers access to more than 25,000 vehicles of all different makes, models and manufacturers dating to 1988 and eliminates guesswork during extrication.

At press time, CRS was in the early stages of testing in Calgary but it had already shown promising results including black box or event data recorder removal for police investigations, hybrid battery shutdown and magnesium metal component locations during a vehicle fire.

The program can be loaded onto a tough notebook or a laptop to bring to the incident scene. Depending on which software version your department buys, rescuers can physically identify the vehicle by visible description or manufacturer nameplate.

Vehicle model upgrades and components are constantly updated via the Internet to give rescuers the latest information about new vehicle design technology.

The challenges of new technology

Car manufacturers have developed many innovative, passive safety devices to protect vehicle occupants. Vehicles have come a long way from the inception of a single crumple zone in the front frame rails back in the 1980s to an effective, energy absorbing management system that tremendously increases the passenger survival space.

Still, with every improvement to occupant safety, there is often a drawback or downside for rescuers performing patient extrication. Even with all the design improvements and collision avoidance systems, there are still high speed crashes and occupants continue to be pinned in vehicles.

For example, supplemental restraint systems that protect occupants during a crash can seriously harm an unsuspecting rescuer because not all airbags and roof curtains deploy in all crashes. Inadvertently cutting into a 10,000 psi, undeployed metal cylinder while removing a roof can have disastrous results for rescuers and patients. Unfortunately, vehicle manufacturers do not place these cylinders in common locations. The cylinders can be found anywhere in the roof area of a vehicle.

Another challenge for rescuers is, of course, high-strength steel locations. These areas can be extremely difficult to cut unless rescuers have the latest hydraulic tools; even then, the operator’s cutting skill and knowledge plays a role.

With hundreds of vehicle makes, models and designs, it is impossible to memorize the locations for all these restraint systems and high-strength steel components. Even 12-volt batteries are not in the same place they were a few years ago, as electrical power shutdown has become paramount in helping rescuers prevent an undeployed airbag from going off during extrication procedures.

What about hybrid vehicle technology?

Environmentally friendly vehicles are becoming a way of life as consumers demand cost-efficient solutions to reduce fossil fuel emissions. Most modern countries have or are about to introduce emissions legislation. The move to clean fuel has sparked a drive for hydrogen and hybrid vehicles with complex power trains solutions that contain lithium ion and nickel metal hydride high-voltage batteries and components. These systems pack a lethal punch of high-voltage electricity that needs to be respected during extrication and have specific shutdown procedures. Power isolation is forefront to make these vehicles safe to work around for first responders.

It’s easy to understand, then, why our platinum 10-minute time frame from arrival to patient removal has increased.

Understanding CRS

The Crash Recovery System provides all the details rescuers need in an understandable format, while allowing the safe performance of their duties.

One software option is the VIN edition, a program which allows rescuers to type in the vehicle identification number and bring up the make, model and year of the vehicle in question.

This program can also accommodate a bar code scanner tool that can capture the barcode VIN number in newer model vehicles and put the particular vehicle onto the laptop screen with the squeeze of the trigger.

Some benefits of the CRS for first responders are:

Available technical information about components of the vehicle involved in a crash can reduce extrication time and increase overall safety of rescuers and patients;

Vehicle-specific information can reduce training time, because rescuers do not need to learn details about different mounting locations for relevant components (batteries, roof curtain inflators, pyrotechnical pre-tensioner devices);

Knowing exactly where a component is located is better than spending valuable time searching for it;

Knowing where the high-strength steel is placed in a vehicle saves time.

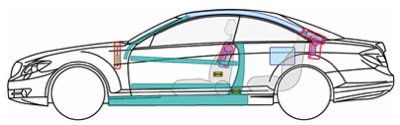

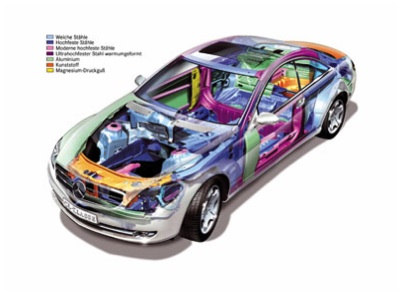

Here are some examples from the Crash Recovery System about particular vehicles (all are screenshots taken from the software). Vehicle components are colour coded for easy identification

Body construction and reinforcements

Hood struts are shown for rescuers to avoid cutting and for a possible hazard during fire. Note the heavily reinforced rocker panel highlighted in blue – rescuers will note the tensile strength of the steel and this will help determine what tool to use to cut. A reciprocating saw would prove to be ineffective on this component and thus a waste of valuable time.

|

|

|

Mercedes Benz CL

|

Mercedes-Benz CL

Reinforcement pipe inside A-pillar. If you know where it is located, you can work around it or adapt your strategy (e.g., flap the roof to the front).

Vehicle information can also be helpful while determining Plan A, B and C. Tactics can be tailored to the actual components of the vehicle.

|

|

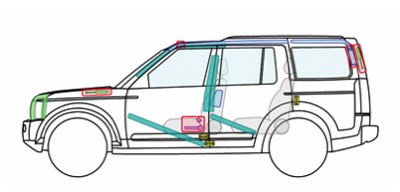

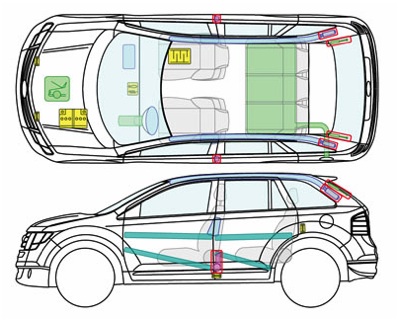

| Land Rover LR4

|

Land Rover LR4

Reinforcement in B-pillar. It’s easy to see how you can work around this particular high-strength steel component. Keep in mind that there are vehicles in which the complete B-pillar is reinforced from top to bottom. This is where the knowledge and skill of the tool operator plays a big part. For late-model vehicles, rescuers need up-to-date hydraulic cutters. Note the green colour at the front of the vehicle; this signifies that this make and model of Land Rover has magnesium in the area and will be a serious hazard during a vehicle fire. Water and magnesium do not mix well!

|

|

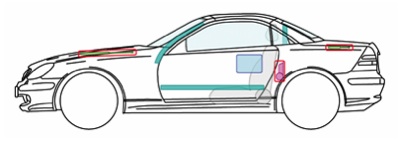

| Mercedes Benz SLK Convertible

|

Mercedes-Benz SLK, convertible

If the best plan is to relocated the roof, then there are several options to consider:

Plan A: Use the electric release

Plan B: Release the roof from the windshield frame and cut the C-post.

Plan C: Cut A- and C-pillars. Cut above the reinforcement.

|

|

| Mercedes Benz SLK

|

Keep in mind that although this program is an excellent resource, it should not replace training. But it can be helpful to find the optimal course of action.

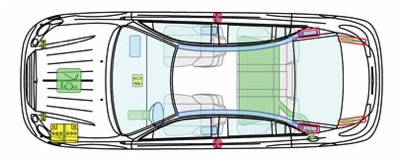

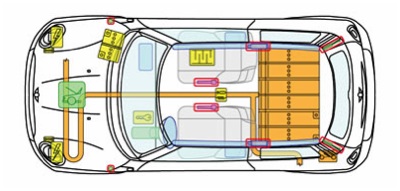

2010 Ford Edge

Airbags

This vehicle is a 2010 Ford Edge equipped with frontal airbags for the driver and passenger, seat-mounted side airbags and a curtain airbag on both sides and for all rows of seating. The airbag control unit is on the centre tunnel of the vehicle under the dashboard. No further scanning for undeployed airbags is necessary; deployed airbags will be obvious. The yellow, colour-coded box under the engine hood is the 12-volt battery. Click on the box and text appears explaining the disconnection procedure and capacitor drain-down time.

|

|

| Ford Edge

|

Roof curtain cylinders are visible in the middle of the rear C-pillars, along with the pyrotechnic seatbelt pre-tensioners in the lower B-pillar. The hood release symbol indicates how to locate the hood release and unlatch it for quick access. Both pictures and text will be shown.

|

|

|

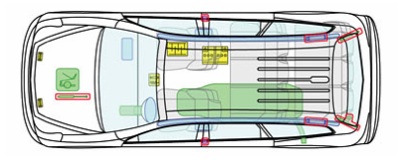

Chevrolet Traverse

|

Chevrolet Traverse

Performing electrical shutdown is much quicker if the battery location is known. On this Chevrolet Traverse, the battery is below the passenger’s seat and can be accessed through an opening in the floor of the vehicle.

|

|

|

|

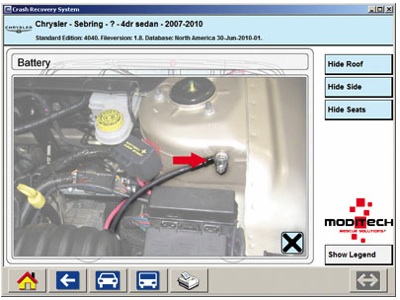

| Chrysler Sebring

|

Chrylser Sebring

The battery of this Chrysler Sebring is in the wheel well area of the vehicle. Even if you know where it is, it is very difficult to disconnect it. Additional information may be helpful. As you can see, the negative battery terminal can be disconnected from the body of the vehicle on the strut tower in the engine compartment.

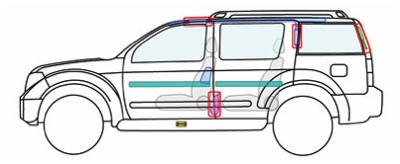

Nissan Pathfinder

Looking at the side view of this Nissan Pathfinder, the location of the high-pressure cylinders for the roof curtain airbags is apparent. Cutting around these components is essential when removing the roof section. Furthermore, this schematic reveals that a seatbelt pre-tensioner is mounted at the base of the B-pillar and a pressurized strut is supporting the rear hatch.

|

|

| Nissan Pathfinder

|

With this information, a lot of vehicle-specific issues when dealing with airbags are solved. All you need to do is to maintain safe distances from the undeployed airbags, stay clear of the high-pressure cylinders when cutting and shut down the electrical system.

Alternative propulsion

Every vehicle has some components that must be avoided. This also applies to vehicles with alternative propulsion, as they will have a lot more potentially hazardous systems as seen below:

|

|

| 2010 Mini Cooper

|

2010 Mini Cooper

This 2010 Mini Cooper carries a lithium ion battery where the rear seats are normally found. The high-voltage cabling running from the large battery pack to the engine compartment is shown in orange. It’s important to know where these components are and to avoid handling them. It’s also important to know how the propulsion system and high-voltage power can be disabled. Built-in safety devices should normally shut down the propulsion system when any airbag deploys. However, in some types of collisions, airbags will not deploy because of the crash characteristics. It’s difficult to determine whether the system has been deactivated or not. Responders should know the procedure to disable the propulsion system. While this procedure is again vehicle specific, easy to understand step-by-step instructions on system shutdown will be extremely helpful.

These are just a few examples why it is imperative to have up-to-date, vehicle-specific information readily at hand to deal with the hazards of today’s vehicles. CRS contains vehicle schematics for all vehicles and a number of heavy trucks on the market; you’ll be surprised to find the different and obscure locations of some of these potentially hazardous components.

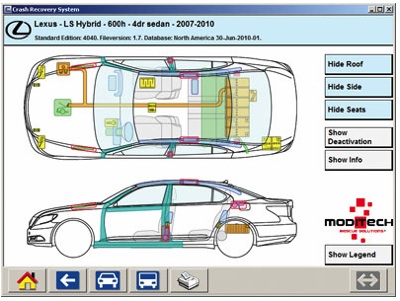

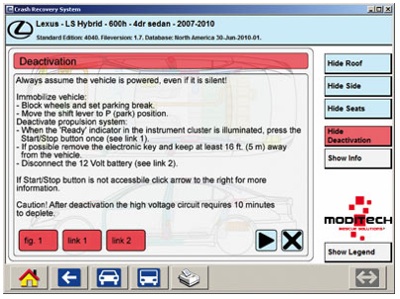

|

|

|

|

| Lexus LS – Hybrid

|

Information can never replace training, but it can help tailor the extrication and increase overall safety for everyone at the scene.

|

|

| Lexus LS – Hyrbid Fuse

|

CRS software is available through local Hurst dealers or contact Tina Arndt at 800-537-2659 ext. 2068 or visit www.jawsoflife.com.

Calgary firefighter and extrication instructor Randy Schmitz has been involved in the extrication field for 17 years and has competed in all levels of extrication competition including world challenges. He is the Alberta chairman for Transport Emergency Rescue Committee in Canada , chairman of the T.E.R.C. Canada educational committee and a judge for T.E.R.C. Canada and U.S. He can be reached at rwschmitz@shaw.ca

Print this page