Extrication Tips: January 2010

Randy Schmitz

Features Extrication TrainingIn September, I instructed at a two-day big rig rescue symposium in Nisku, Alta. The other two lead instructors were Billy Leach Jr. from North Carolina and George Klemm from Vancouver Island.

In September, I instructed at a two-day big rig rescue symposium in Nisku, Alta. The other two lead instructors were Billy Leach Jr. from North Carolina and George Klemm from Vancouver Island. The first morning was devoted to theory and discussions of large-vehicle anatomy and construction, challenges for rescuers, correct cribbing applications and load-bearing equipment.

The remaining day and a half was spent working with simulated, large-truck accidents involving passenger vehicles. Students rotated through scenarios and spent three to four hours learning the proper ways to approach, stabilize, lift, then extricate patients from crushed wrecks. First, the students dealt with the situation as though the incident had happened on a rural highway outside of a city and they had responded with their own departmental resources; then, they played out the scenario with the assistance of a heavy wrecker tow truck that had arrived on scene after a certain length of time.

In this column and the next two (in April and July) we will look at the program content and what students learned, including large-vehicle classifications, anatomy, construction, arrival hazard control, stabilization, disentanglement and patient removal from the crushed passenger vehicle and the cab of the truck. In the final issue of 2010, in October, we’ll run an exam, with the answers available on the Canadian Firefighter/Fire Fighting in Canada website (www.firefightingincanada.com).

|

|

| Photo 1: Scene of rollover. | |

|

|

| Photo 2: 2010 International Lone Star. |

|

|

|

| Photo 3: By removing the thin rubber bead in the middle of the gasket the window will fall out. |

|

|

|

| Photo 4: The red button pictured here raises or lowers the driver’s and passenger’s seats. | |

|

|

| Photo 5: These piano-style hinges run the length of the door and are stainless steel. | |

|

|

| Photo 6: There are likely to be casualties in crashes involving long-haul semi trucks with sleeper units if occupants are sleeping inside the compartment. |

|

|

|

| Photo 7: Battery box under driver’s door used as a step into the cab. |

|

|

|

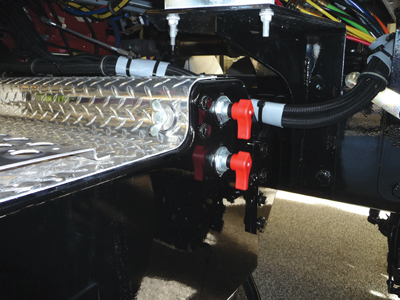

| Photo 8: Battery shut off switches on some newer model Kenworth T660s. |

|

|

|

| Photo 9: 12-volt batteries wired in parallel located directly under driver’s door. |

|

|

|

| Photo 10: Thermo King refrigeration unit, or Reefer, used for meat and produce; runs on a separate diesel fuel tank underneath the trailer. |

|

|

|

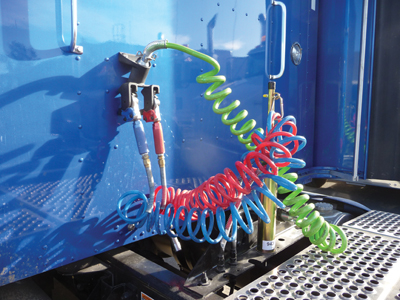

| Photo 11: Pogo stick, glad hands and trailer wiring. Advertisement

|

Volume of truck traffic

According to the U.S.-based National Highway Traffic Safety Association (NHTSA), every year for the last 10 years there has been an average of about 5,500 large trucks involved in fatal crashes in North America – 550 in Canada and 4,500 in the United States. In addition, 100,000 large trucks were involved in injury crashes every year and, since the late 1970s, 12 to 13 per cent of all traffic-related fatalities in North America have been the result of crashes involving large trucks.

The NHTSA data suggests that drivers of passenger vehicles may have contributed to the crashes more than the drivers of the large trucks. However, a speed limit of 100 kilometres an hour or more, poor weather conditions and curved roads significantly increased the likelihood of rollovers and jackknifes of large trucks. Driver fatigue and inattentiveness were also listed as factors in crashes for drivers of both passenger vehicles and large trucks.

Weight classifications

The weight of large trucks varies but these vehicles are basically categorized as medium or heavy. Classes 3, 4 and 5 are considered medium-duty trucks and have a gross vehicle weight rating (GVWR) of between 4,500 kilograms (10,000 pounds) and 8,844 kilograms (19,499 pounds). Classes 6, 7 and 8 fall into the heavy duty truck category and their GVWR falls between 8,845 kilograms (19,500 pounds) and about 15,000

kilograms (33,001 pounds).

Anatomy of a semi

There are a number of different truck designs. Straight trucks are built on solid frames and are not designed to pull trailers. A lot of these trucks have two to three axles. Specialty trucks are designed for particular purposes and include concrete haulers, dump trucks, heavy wreckers and fire trucks. Another common type of truck is the semi-trailer combination. It is estimated that 60 per cent of trucks on North American highways are semi-trailers. These consist of a truck – known as either a bobtail or a tractor – and two or three axles. The average weight of a tractor minus the trailer is between 8,100 kilograms (18,000 pounds) and 9,900 kilograms (22,000 pounds).

Cabs of these large vehicles are called either conventional or cab-over units. The conventional unit is the most popular design and features the cab behind the hood and engine. The hood and front fenders are usually moulded in plastic or fibreglass because of the complex aerodynamic shapes. The front bumper may be stamped and drawn from steel or aluminium, or it may be moulded in plastic and backed with a steel substructure. The cab-over is positioned above the engine. The cab-over design, or flat-nose, tilts forward to gain access to the engine compartment for maintenance and repair. Construction of either cab styles incorporates steel, aluminium and fibreglass and a new, lightweight product called Metton (www.metton.com) for aerodynamics. The cab roof is generally one of the weaker components of the cab and usually consists of two lightweight ribs surrounded by light-gauge material. Mounted on the roof area is a fairing usually made of fibreglass or Metton, an air-conditioning unit, air horns and possibly a GPS locator.

Windshields are made of typical laminated safety glass that is surrounded by a thick rubber gasket; standard tempered glass is used for the side windows and in the doors. Driver’s seats on newer trucks are powered pneumatically through buttons on the side of the seat cushion or a pull/push button under the seat. A tip for rescuers: if you are unsure which button will move the seat up or down, choose the red one.

Large truck cab doors are built somewhat stronger than doors on passenger vehicles, with heavier gauge steel; the hinges are either piano-style hinges (which may be made of stainless steel in newer models) that run the length of the door, or standard, passenger-vehicle type hinges. The latching mechanisms for large truck doors are located in the centre of the door, as one would expect, but because of the height of the vehicle the door handle is placed in an easily accessible position at the lower corner of the door.

Accommodations

Most long-haul semi units have what’s known as a sleeper; this allows the other drivers to rest if the number of driving hours exceeds the legal limit. The sleeper unit is a compartment mounted behind the cab that can have upper and lower bunk beds for sleeping. Inside decor can be basic or it may have more elaborate luxuries such as a microwave, a wall-mounted TV, closet compartments, a sink, a fridge, a toilet and even a shower.

Typical construction features a multitude of materials ranging from steel, fibreglass, sheet metal and aluminium stud walls to wood, fabric and plastic. Breaching the walls of these sleeper units can lead to problems if the above-mentioned appliances are mounted on the walls. Access is common via the cab but some compartments have access doors on the driver or passenger side of the unit. It is highly anticipated that there will be casualties in crashes involving long-haul semis with sleeper units if occupants are sleeping inside the compartment.

Because of the long-haul nature of semis and the high fuel demands required to supply the diesel engines, these trucks may have up to two aluminium saddle tanks. These tanks can have a capacity of between 200 and 600 litres (50 to 150 gallons). These tanks can be on either side of the truck in various locations.

Electrical system requirements for semis are usually 12- or 24-volt batteries, wired in parallel to each other, housed in aluminium or metal battery boxes and can found directly under the doors (and often used as a step into the cab). A battery shut-off switch on some of the new trucks can be found on the side of the battery boxes; rescuers should keep an eye out for this handy option.

Typical compressed air brake systems are common in larger trucks. Components of these kinds of systems include air-tank reservoirs, supply lines, air chambers or piggy-back chambers with large springs that mechanically engage the brake drum or disc under each axle in case of loss of air.

Air-ride suspension is very common. This uses flexible, air-inflated, rubber bags know as bellows; these are attached to the truck axles where metal leaf springs would normally be found. This system allows for a smoother ride. The air pressure within the bag is monitored electronically and adjusted to accommodate the weight of the load and changing road conditions.

Trailers

One or more trailers can be attached to the tractor. Common names for these multiple trailer units are B-trains or super Bs. Some different trailers you will encounter are flat beds, end dumps, box trailers for hauling regular cargo, product haulers called dry bulkers, fuel tankers, reefers or refrigeration units, and lowboys for hauling heavy equipment.

A complete tractor-trailer unit can legally weigh up to 36,360 kilograms (80,000 pounds) but can go as high as 62,500 kilograms (138,000 pounds) if special permits are issued.

Products that are commonly transported are pressurized and non-pressurized liquids, corrosive materials and compressed gases, to name a few. That being said, the metal used to construct these trailers varies considerably. A box trailer or van trailer used for hauling product, for example, is constructed of relatively light-gauge metal, such as an aluminium stud frame, with wood and thick insulation lining the inside of the trailer. Refrigeration units are of similar construction on the outside but have spray foam insulation and fibreglass sheeting on the inside, with a ribbed aluminium floor, whereas compressed gas tankers weigh considerably more, are made from heavy gauge steel with piping and other components, and have placards attached indicating their hazardous content. Livestock trailers present another challenge for rescuers because of their distinctive construction (the interiors of these trucks can be changed and sectioned) and the unique nature of the cargo – live animals. (Incidents that involve livestock trailers are to be handled in a certain way and will be addressed later.) One important design change: because of a federal mandate to reduce diesel fuel consumption by six per cent over the next two years, trailer manufactures are installing fibreglass or Metton skirting underneath trailers to reduce drag and wind resistance. With this in place, fuel tanks that are installed on the underside of trailers that supply refrigeration units will no longer be visible to unsuspecting rescuers.

Most new trailers also have air-ride suspension components. Since semi-trailers rest on top of tractors they have high centres of gravity, which makes them less stable than straight truck rigid vehicles.

Tractors are coupled to trailers via a pivot point known as the fifth wheel, which is bolted on to the top of the tractor chassis above the rear axles. The fifth wheel has a large steel plate that can pivot and adjust to the height of the trailer, which mates with a kingpin and is then locked with two steel jaws. Most trailers have landing gear near the front to allow them to free stand when uncoupled from the tractor. To raise and lower the load there is a gearbox attached to the landing gear that has two speeds, slow or fast, with different gear ratios. Pulling out the crank handle, or pushing it in, allows for different mechanical advantages. The landing gear can come in handy for supporting or raising the trailer in an emergency situation for rescue.

To add braking power to the trailer, glad hands are coupling devices used to connect the service and emergency airlines from the truck to the trailer. The couplers have a rubber seal, which prevents air from escaping. To connect the glad hands, the operator presses the two seals together with the couplers at a 90-degree angle to each other. A turn of the glad hand attached to the hose joins and locks the couplers. The service airline is colour coded blue and the emergency airline is red. For flexibility of the lines when the trailer is turning, the lines themselves are attached to a flexible pole called a pogo stick. An electrical link is made between the tractor and the trailer through a cable called a pigtail. This cable is a collection of wires in a single sleeve. Each wire controls one of the electrical circuits on the trailer, such as running lights, brake lights and turn signals.

This should give you a basic understanding of the anatomy and construction of common large vehicles and trailers. It is important to understand and learn the new technologies and materials on these vehicles. Rescuers should visit their local truck dealerships and see first hand the changes that have taken place in truck and trailer design to get a thorough understanding of what they will be dealing with on the roads and highways.

In the next issue we will focus on arrival, hazard control, stabilization and extrication operations.

In the meantime, stay safe!

Randy Schmitz is a Calgary firefighter who has been extensively involved in the extrication field for 17 years. He is an extrication instructor and has competed internationally. He is the education chair for Transport Emergency Rescue Committee (T.E.R.C.) in Canada, a T.E.R.C. International extrication judge and a tester and evaluator for manufactured prototype products for extrication equipment. He can be reached at rwschmitz@shaw.ca

Print this page