Tim-bits: January 2019

By Tim Llewellyn

Features Equipment Hot TopicsHopefully, every fire department has some kind of written policy or standard practice that requires regular, documented apparatus and equipment inspections.

Like all fire equipment Hopefully

Like all fire equipment HopefullyI’m not talking about annual professional maintenance. I’m talking about the daily or weekly checklist inspections performed by firefighters. In the fire departments that I’ve been involved with, these “truck checks” serve as a way to ensure that the apparatus and all of the equipment on them are service-ready.

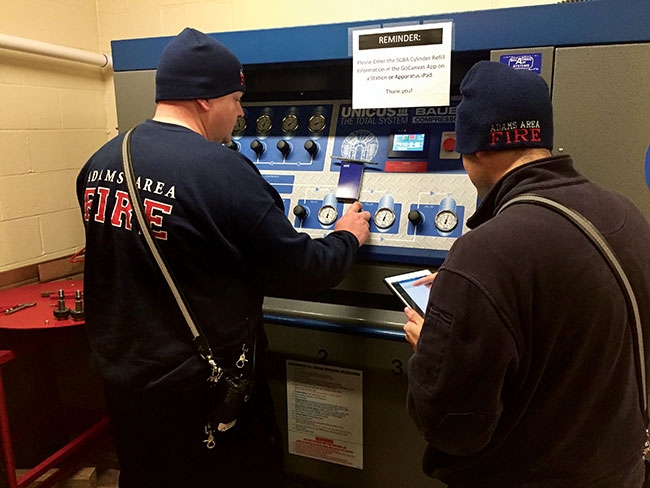

One item that I feel is most important to check is the self-contained breathing apparatus (SCBA). Properly functioning SCBAs are vital to many fire department incidents. An SCBA that is not service-ready can make a negative difference in a life and death situation.

Here are the basics that I look for when conducting a check of an SCBA:

- Are the straps fully extended and not twisted?

- Are any components missing, worn or broken?

- Does the unit have adequate power in the battery pack?

- Is the bypass valve open or closed?

- Is the main high-pressure air line connected securely to the cylinder?

- And, most importantly, is the cylinder filled to its maximum, optimal, full pressure?

Some departments that use 4,500-pounds-per-square-inch (PSI) cylinders are in the mindset of filling up or topping off the cylinders when pressures fall below 4,000 PSI. Other departments that use different SCBA cylinder pressure types usually have a similar range of acceptable pressures. As long as the cylinders are within the defined range, they are okay to be in service on the fire apparatus.

I’ve been in places where a significant amount of emphasis and energy is placed on the amount of fuel in the fire trucks. Some places say, “The fuel level in the apparatus shall be maintained at full at all times. You never know how long the truck will be on a call and you don’t want to run out.” I would like to see this same mentality and energy applied towards SCBA cylinder pressures.

The working duration of an SCBA cylinder is dependent on many things such as work-load or exertion, relative fitness of the user, the presence or absence of any SCBA facepiece seal compromises, any other leaks in the unit and, most importantly, the beginning cylinder pressure.

I truly believe that if we want to give our customers the best service possible, we need to ensure that our SCBAs give us the opportunity to solve problems. If an extra 200 to 300 PSI could allow us to finish the search of a room or search another bedroom or to make sure a hose would stretch down another hallway, we would win.

Put another way, if things go bad for us or if we get trapped or lost in a smoke-filled structure, the additional 300 to 400 PSI in our cylinder would allow precious moments of clean air to breathe before the RIT team arrives. It could mean life or death for us or them.

But seriously, how much time will 300 to 400 PSI actually provide? It can’t be that much, right? Allow me to introduce you to the “500 Drill.” The 500 Drill was presented to me in my formative fire service years by a group of great instructors, mentors and friends from the Pittsburgh (PA) Bureau of Fire. The 500 Drill occurs after any regular SCBA training and is typically one of the last events for the session.

Train on any topic, whether it be hose advancements, searches or car-fire simulations and have the firefighters do it “on air,” breathing from their SCBAs. Once all objectives of the drill are met, have each firefighter continue to breathe down or bleed off their cylinders until only 500 PSI remains. When each cylinder’s pressure is at 500 PSI, tell the firefighters to stop the air flow to let everyone catch up. Lots of quarter-service or one-third service alarms will be sounding, so hearing protection should be considered.

With everyone’s cylinder at 500 PSI, start some kind of continuous movement, group activity and start a stopwatch. Play dodgeball, basketball, freeze tag or start some kind of specific fire-service training. A self-rescue search maze is great to throw in here to practice firefighter survival skills under an actual “low-air situation” kind of stress.

The main goal of the 500 Drill is to get firefighters to understand how much time and movement and work can be done on 500 PSI in an SCBA cylinder.

Instruct each firefighter to continue his or her assigned activity until their low-air alarm stops sounding. Once the alarm stops, have each firefighter come to a resting position and continue breathing. Do not shut off the regulator or remove the mask at this point.

There will be air remaining for breathing after the alarm stops. Have the firefighters count their breaths until the cylinder is completely empty and the mask “sucks” to their faces. Once this occurs, coach them to calmly remove the regulator from the mask and breathe normally. Mark the time for each firefighter. Once every firefighter has completed this, discuss with the group the amount of time for each and have everyone state how many breaths they took after the low-air alarm stopped.

Unless they have done this before, every firefighter will be surprised at how much air remains after the alarm stops. Ask them to imagine how a firefighting effort would have been different if their SCBA cylinder pressure started out at 4,000 PSI instead of 4,500 PSI. Apply it to a real-world scenario.

The take-home message for the 500 Drill is that 500 PSI matters. Lots of work and movement can occur on 500 PSI. Lots of searching and firefighting and self-rescue can occur on 500 PSI. SCBA cylinders should be full at all times.

I encourage each of you to try the 500 Drill at your departments and see for yourselves how much 500 PSI matters.

Tim Llewellyn is a firefighter for the Allegheny County Airport Authority in Pittsburgh, Penn., and an instructor for a number of fire academies and training faculties. llewllyn.fire@gmail.com

Print this page