Extrication Tips: A couple more hidden problems

Chad Roberts

Features Extrication canadian firefighter editors pick firefighter firefighter training Exterior view of the more common compressed gas strut.

Photo: Chad Roberts

Exterior view of the more common compressed gas strut.

Photo: Chad Roberts The world of auto extrication and as it relates to the fire service has been inundated with the topic of electric vehicles and how they are powered by lithium-ion batteries. Vehicles themselves are not the only cause for concern when it comes to the dominating battery power source. Laptops, cell phones, scooters and many more things in our lives are being driven by lithium-ion, so this topic in the fire service rightfully deserves the front row. While this will be a topic I will continue to dive into, I wanted to take a brief side bar to talk about a couple hidden issues that some of you may or may not be aware of.

These issues were some things that we knew of but were made more apparent when I had the opportunity to dissect some new model vehicles in Philadelphia this past spring.

Interior view of newer struts that encompass a spring instead of compressed gas.

Photo: Chad Roberts

The first issue I want to touch on is the different type of struts that we are starting to encounter on newer vehicles in relation to the rear hatches or tailgates of vans, SUVs and hatchbacks.

Even when making the cuts with the appropriate tools and placement, a hazard still exists.

Advertisement

These struts are widely considered to be powered by the presence of inert gas stored in a cylinder. Like mentioned in earlier articles, these devices are to be avoided when using the hydraulic cutters; however, the use of a Sawzall can make a safe release of these gasses when the cylinder absolutely needs to be cut. Where this became an issue in our recent training was in some newer model vehicles that feature struts of a different construction. Instead of the inflation cylinder being filled with gas, these newer options are spring loaded and spindle driven by electric motors to facilitate power tailgates. Noted by a generally larger cylinder size, when cut with a hydraulic cutter or Sawzall, these springs can come shooting out at very high speeds, creating a projectile much like an air bag inflation cylinder.

Exterior view of a newer strut with a compressed spring inside.

Photo: Chad Roberts

Even when making the cuts with the appropriate tools and placement, a hazard still exists. The safest bet when dealing with these may be a very cautious approach, and/or exposing these hazards by popping the hatches and removing them from their attachment points with either a pry bar or disassembling them altogether with the appropriate size socket and impact gun or torx bit. Once fully removed or disassembled, just remember that someone will need to be dedicated to hold up this hatch until it is fully removed.

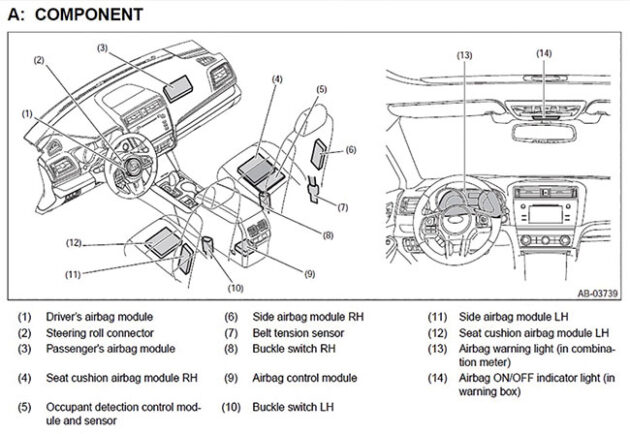

The next hazard that was identified with these newer vehicles was, again, not something new to us but more a new location to find it in. With the introduction of more elaborate SRS systems, we are continuing to see new locations and designs of air bag systems everywhere in vehicles. This one was a new air bag that was located in the driver and passenger seat back. While this isn’t usually a huge cause for concern, the location of the inflation cylinder was the real issue. With our plan to mitigate the seat back and no use of the 12volt power available, we started disassembling the seat to ensure our proper cuts. Located in seat back, very close to our cut location, was the air bag inflation cylinder that could have easily been overlooked.

Components 11 and 12 show the airbag module hidden inside the seats of newer model vehicles.

image: Chad Roberts

With power seats the norm in almost every vehicle, overcoming seat back issues will continue to be prevalent. Also, with this maneuver generally being left until the near end of the extrication process, proper exposing and identifying of these hazards can often be overlooked. Therefore, with these new air bag cylinder locations in mind, we need to remember early identification of electronic seat backs and the use of 12volt power before it’s disconnected. If this isn’t possible, we need to continue to be vigilant and properly expose and identify all areas of the vehicle before we push off or cut.

The previous two examples hopefully will help shed some light on not just those two specific issues that were identified. However, they should serve as a stark reminder that new vehicle technology issues aren’t just EV and battery related. They can surface in the form of new ideas on old materials, much like the hatch struts or the addition of more safety features and SRS systems in locations not previously expected.

Chad Roberts is a firefighter in Oakville, Ont. He is a member of the Oakville extrication team and competes and trains across North America. Contact Chad at chadroberts12@gmail.com.

Print this page

Advertisement

- Two people taken to hospital after e-bike catches fire in Yorkville apartment

- Montreal fire department carries out hundreds of inspections after deadly March blaze